APAC Controls is your trusted partner in PLC and HMI Design and Programming solutions. At APAC Controls, we specialize in providing cutting-edge automation solutions tailored to meet your business needs. Our team of skilled experts in PLC (Programmable Logic Controller), DCS (Distributed Control System), HMI (Human Machine Interface) and SCADA (Supervisory Control and Data Acquisition) systems ensuring seamless integration, advanced control solutions, efficient modernization and upgrades for your industrial processes.

PLC & DCS Programming

Our team of experts delivering efficient, reliable and quality control solutions for your manufacturing processes.

We work for variety of industries and offer full scope of PLC and DCS systems services including:

- System architecture design.

- Developing cutomer specific programming standards.

- PLC and DCS programming in compliance with the industrial standards.

- Integration of various types of communication interfaces and third party devices.

- Exisitng system analysis with recommendations for upgrades, maintenance and recovery options.

- Modernization and Upgrades

- Maintenance and Support

- Legacy systems migration

- Complete process simulation for certain systems

Well-versed in popular PLC programming software platforms such as:

- Siemens STEP 7 and TIA Portal.

- ABB 800xa and Symphony Plus.

- Rockwell RSLogix 5,500,5000 and Studio 5000

- Schneider Electric Proworx, Concept, Unity Pro and Control Expert

- Automation Direct Do-More Designer and others

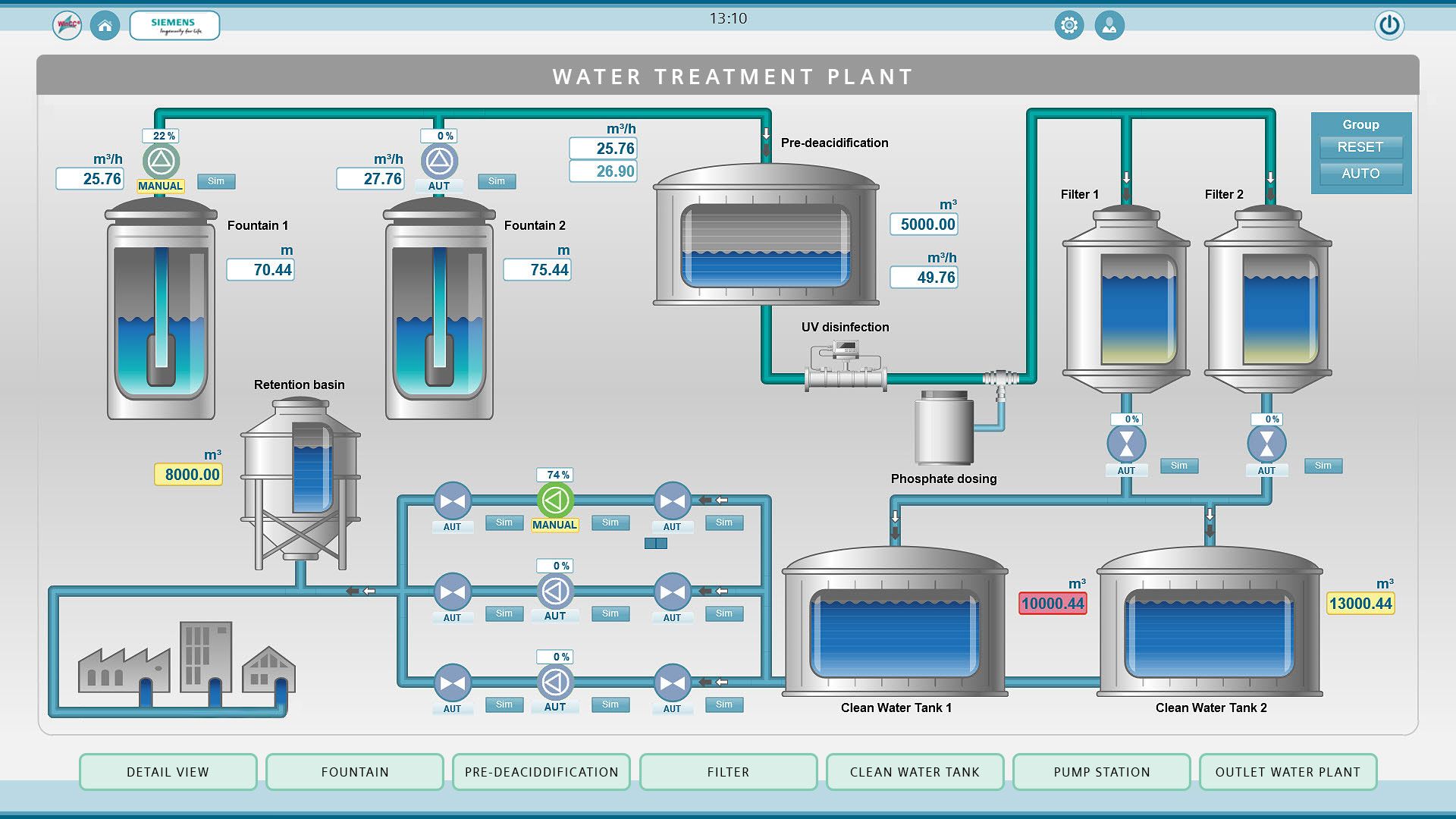

HMI & SCADA Design

At A-PAC Controls we tailoring HMI (Human Machine Interface) and SCADA (Supervisory Control and Data Acquisition) designs to meet specific customer needs and industry requirements. From manufacturing to process control, we deliver HMI and SCADA graphics that optimize operations and makes production process more safe and efficient by providing proper ineraction between control room operators and process graphics.

Our team have extensive experience in integrating HMI and SCADA systems with PLC (Programmable Logic Controller) and DCS (Distributed Control System) control hardware, creating a comlete automation solution.

We can offer wide range of HMI and SCADA services:

- Graphics design and development for various types of Operator interfaces like local touch panels, workstations, servers and etc.

- Developing customer and industry specific custom standards and templates.

- HMI and SCADA systems migration, upgrade, and modification.

- Reporting and Notification solutions

- Data storage and analytics.

- Alarm management.

Our proficiency extends across various HMI and SCADA platforms, allowing us to work with a wide range of hardware and software, ensuring compatibility with existing systems:

- Inductive Automation Ignition

- ABB 800xa and Symphony Plus

- Rockwell FactoryTalk

- GE iFix

- Siemens WinCC and others

Industrial Automation

With a proven track record in industrial automation, A-PAC Controls is a dynamic force delivering efficiency and innovation in the manufacturing and utilities sectors. Our team of experts excels in designing, implementing, and optimizing automated systems that streamline production, enhance quality, and boost overall operational performance.

Key Expertise:

- PLC and HMI Programming

- SCADA Systems Integration

- Robotics and Motion Control

- System retrofitting

- System maintenance: preventative and emergency

- Installation and maintenance

- Testing and start-up

- On-site commissioning

- Field services

- IoT and Industry 4.0 Solutions

- Customized System Design

- Safety and Compliance

Technical Support

At A-PAC Controls, we understand the need of expertise and technical insights in uncommon situations with different level of urgency. With a team of dedicated experts, we provide immediate assistance to our clients in solving complex technical problems. Our proficiency spans across a wide range of industries, ensuring that our clients receive solutions that meet their unique needs.

Key Highlights:

- Various Industry Knowledge

- Proactive Issue Resolution

- 24/7 Availability

- Custom Solutions

- Remote Troubleshooting Capabilities

- Clear and Concise Communication

- Continuous Learning and Adaptation

- Customer-Centric Approach