In a modern world where hi-end technology and most powerful computer systems is available for the wide range of consumers at affordable cost it is very important to understand how it can be efficiently utilized to empower your business operations, increase production capabilities, and optimize process safety.

Simulation is the most efficient way to visualize, review, analyze, and validate production processes and automation concepts.

At A-PAC Controls we provide a wide range of process simulation solutions and services for a variety of industries and types of technological processes.

Our mission is to deliver to our customers cost efficient simulation products that will help to solve manufacturing challenges and add value to the business processes that does not require high investments.

Operator Training Simulator (OTS)

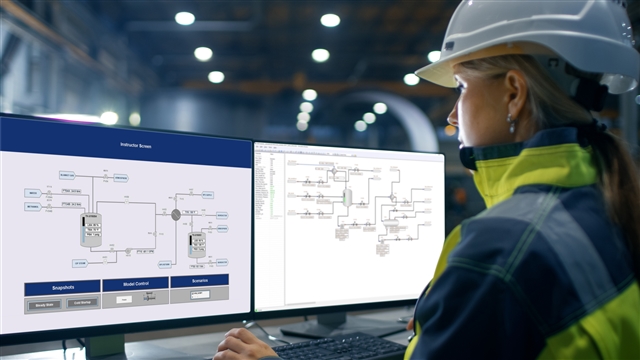

When it comes down to operations whether it is a new personnel, process changes or modified controls it is always good to have something that can help control room operators to get familiar with the new controls, automation solution or production process in general without the risk of destroying or damaging equipment, decreasing or enterly stopping production, potential injuries, and safety violations. And that is where Operator Training Simulators (OTS) come into the play.

Operator Training Simulator is mimicking actual process and field devices using software tools and device libraries where none of the actual production environment is involved and remain in full operational state while control room operators can refine and enhance their process control skills. OTS providing safe and efficient way to train controls room operators under normal operation and abnormal conditions by simulating different type of fault scenarios, levels of production loads, recipes and other potential real life setups where it may cause material and resource losses if personnel is not properly trained to handle these type of situations.

Our Offerings:

- Customized OTS Solutions: Tailored to a specific industries and processes, our OTS solutions replicate real-world scenarios, allowing control room operators to train in a risk-free, virtual environment.

- Realistic Replication: We pride ourselves on delivering highly realistic simulations, ensuring an authentic training experience that closely mirrors actual operational conditions.

- Diverse Industry Applications: Our OTS offerings span to a wide array of industries, including Manufacturing, Power generation, Oil & Gas, Water & Wastewater, Material handling, Healthcare and more. We understand the unique demands of each sector and customize our simulation solutions accordingly.

- Safety-Centric Training: Our simulators allow operators to practice throguh the emergency scenarios and critical procedures in a virtual environment, minimizing risks.

- Scalability and Adaptability: Our simulators are designed to evolve with your organization. Whether you're expanding operations or integrating new technology, our OTS solutions can be easily scaled and adapted to it.

- Ongoing Support and Maintenance: We offer comprehensive support and maintenance services to ensure your OTS continues to deliver exceptional training experiences over the long term.

Please contact us for more information.

Contact us

Dynamic Process Simulation

Every automation project regardless of size and industry has multiple stages in its lifecycle from initial design to factory acceptance test and turning it to production. But the most stressful and unpredictable phase of the project is always startup and commissioning. Validating and testing complex process control loops and automation concepts while working with the real field hardware may lead to unexpected losses which includes, but not limited to, equipment damage, excessive material expense and costs associated with the delays due to incomplete control logic or HMI graphics.

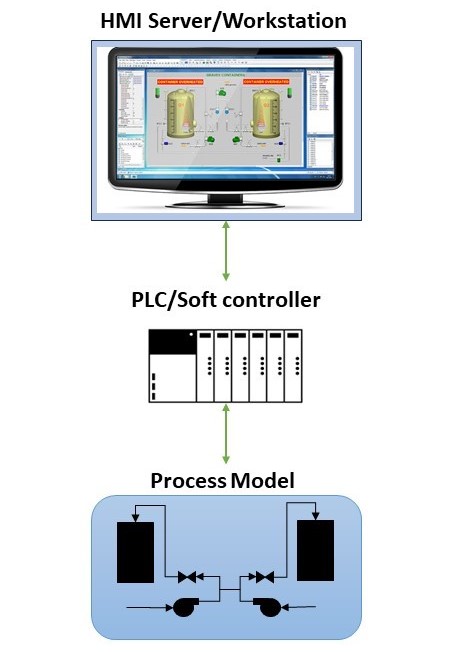

Dynamic process simulation and Digital Twins is the risk-free and effective way to validate, optimize and troubleshoot process control solutions, system faults, and HMI screens ahead of time under the stress-free virtual environment.

A-PAC Controls offers excessive device and process objects libraries along with the user-friendly front-end software that can be linked to the real PLC or SoftController and mimic field equipment and physical process behavior to the point where it matches the real-world conditions.

Our Offerings:

- Process modeling: We specialize in creating simulators that mimic real-world scenarios, enabling professionals to validate and test complex control loops, SCADA and HMI screens, fault conditions, and other automation solutions effectively.

- User-Friendly Interface: Our solutions feature intuitive, user-friendly interfaces that make testing and troubleshooting process more accessible, even for non-experts.

- Safety and Efficiency: We are committed to enhancing safety and operational efficiency through our simulator technology, reducing downtime and risks.

- Cross-Industry Applications: Our simulators find applications in a range of industries, including but not limited to, Power Generation, Oil & Gas, Material Handling, Pharmaceutical, Manufacture and Water & Waste water treatment.

- Scalability and Adaptability: Our simulators are designed to evolve with your organization. Whether you're expanding operations or integrating new technology, our simulation solutions can be easily scaled and adapted.

Please contact us for more information.

Contact us